| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | GDS |

| Model Number : | HTD-600 |

| Certification : | CE |

| Price : | CONTACT US |

| Payment Terms : | T/T |

| Supply Ability : | 30PCS/mon |

| Delivery Time : | 10 days |

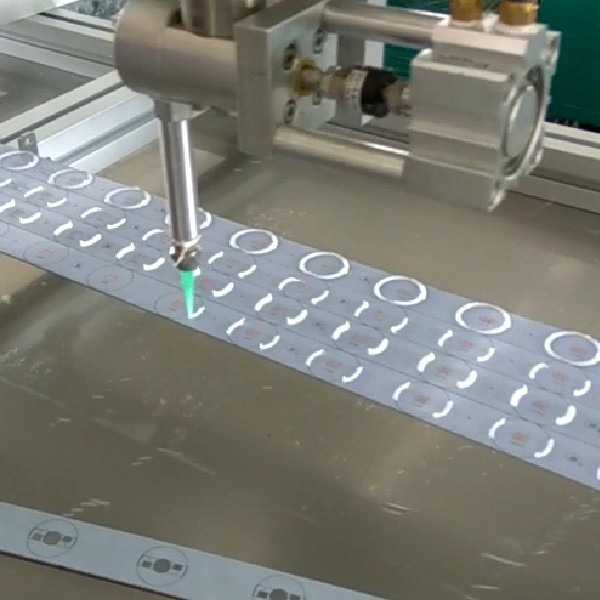

round panel automatic silicone adhesive application by 3 axis glue dispensing robot

Machine Description

The application of silicone adhesive in LED floodlight manufacturing is a critical process that ensures durability, thermal management, and waterproof performance. With the advent of automated glue dispensing robots, this process has been revolutionized, offering enhanced precision, efficiency, and consistency compared to traditional manual methods.

Automatic glue dispensing robots are designed to apply silicone adhesives with high-level accuracy, ensuring uniform coverage across complex LED module geometries. These robots utilize advanced programmable logic controllers (PLCs) to map dispensing paths, adjust flow rates, and compensate for surface irregularities in real time. Such precision is vital for creating reliable seals around LED chips, lenses, and housing components, which must withstand harsh environmental conditions, including temperature fluctuations, moisture, and UV exposure. Silicone adhesives are preferred for their exceptional thermal conductivity, flexibility, and resistance to yellowing, ensuring long-term optical clarity and heat dissipation in high-power LED systems.

The automation of this process significantly reduces human error and material waste. Robots can operate continuously at high speeds, achieving cycle times, while maintaining repeatability across large production batches. Closed-loop feedback systems optimizes bond strength and minimizes defects.

By integrating automated dispensing solutions, manufacturers achieve scalable, cost-effective production with consistent quality—key factors in meeting global demand for energy-efficient LED lighting. This technology not only elevates product reliability but also positions brands competitively in industries ranging from urban infrastructure to industrial lighting, where performance and longevity are paramount.The synergy of silicone adhesives and robotic automation is transforming LED floodlight manufacturing, paving the way for smarter, more resilient lighting solutions.

Machine Features

Technical Parameters

| model | HTD-600 |

| MCU | 3 axis movement controller |

| programming | teaching programming |

| drive mode | Precise Stepping Motor+ Synchronous Belt+ Linear Guide-way |

Working Range(X*Y*Z) | 600*600*100mm |

Max Moving Speed | MAX 500mm/sec |

Repeat Accuracy | ±0.02mm |

Program Memory Capacity | Program Memory Capacity |

Dimension(L*W*H) | 700*650*1200mm |

Working Power | AC220V/50~60Hz/150W |

Working Air Pressure | 0.4 ~ 0.6Mpa(no condensation) |

Working Temperature and Humidity | Temperature: 0 ~ 40℃ Humidity:20 ~ 90% |

Glue applicable

300ml package silicone or 2600ml package silicone

Machine Details

|

|