| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | GDS |

| Model Number : | MG-8080 |

| Certification : | CE |

| Price : | CONTACT US |

| Payment Terms : | T/T |

| Supply Ability : | 30Pcs/Mon |

| Delivery Time : | 10 working days |

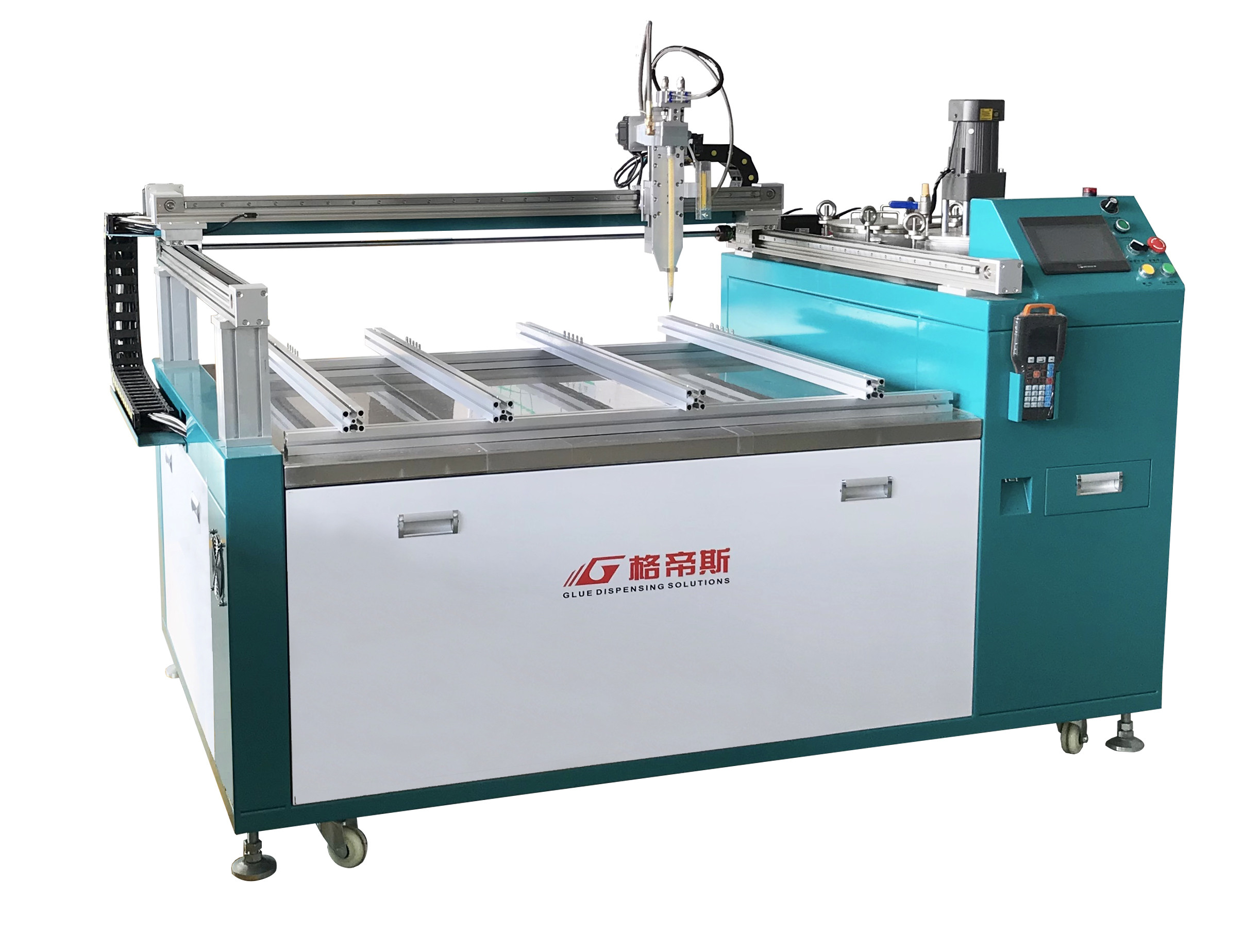

automatic AB glue potting machine for two parts glue filling to inverter

Machine Description

Inverter manufacturing demands precision, durability, and unwavering protection for sensitive electronic components exposed to heat, vibration, and moisture. An automatic AB glue potting machine revolutionizes this process by delivering flawless two-part epoxy encapsulation tailored for inverters.

Why AB Glue Potting Matters for Inverters

Inverters require robust insulation to ensure reliable power

conversion and longevity. Traditional manual potting often leads to

uneven coverage, air bubbles, or incorrect resin-hardener ratios,

risking electrical failures. The AB glue potting machine eliminates these risks with static mixing technology, ensuring a

precise 1:1 (or customizable) ratio for uniform curing. This

creates a seamless, bubble-free barrier around PCBs, capacitors,

and connectors, safeguarding against humidity, dust, and thermal

stress (-40°C to 150°C).

Key Advantages for Inverter Production

ROI-Driven Benefits

By replacing manual labor with automation, manufacturers reduce

rework costs by 30% and epoxy consumption by 25%, all while

enabling 24/7 production cycles. Inverters with extended lifespans,

reduced field failures, and enhanced brand trust.

Machine Features

3 axis mechanical hands employ high precision linear movement module to ensure accurate movement and high repeat accuracy;

Touch screen operation plus handhold teaching programming case, easy to learn and operate;

According to the feature of products and production capacity requirement, fixture and glue delivery head can be customized.

Technical Parameters

| Model | MG-8080 |

| Working Range | 0~500mm/sec |

| Repeat Accuracy | ±0.02mm |

| Mixing Proportion | 100:100~100:10(1:1~10:1) |

| Metering Method | Precise Gear Pump or Screw Pump |

| Mixing Method | Static Mixing |

| Mixing Accuracy | ±1% |

| Glue Extrusion Accuracy | ±1% |

| Glue Container Capacity | 30L 304 Stainless Barrel |

| Glue Viscosity | Max≤20000CPS |

| Glue Additive Proportion | MAX≤100(Glue):100(Additive)(1:1) |

| Glue Additive Size | Max≤400tsp |

| Control Mode | PLC+Handhold Teaching Programming Case+Touch Screen |

| Programming | Teaching Programming |

| Program Capacity | At least 100 unit, 4000 points/unit |

| Transmission Method | Steeping Motor+Synchronous Belt+Linear Guide-way |

| Working Pressure | 0.5-0.8Mpa |

| Working Power | AC220V 50HZ/2000W(stirring,vacuuming, heating not included) |

| Working Temperature | 0-40℃ |

| Working Humidity | 20-90% no condensation |

| Dimension | 1680x1200x1600 mm(WxDxH) |

| Weight | About 350KG |

| Optional Functions | Glue container stirring, pre-heating, vacuum degassing, self-cleaning |

Machine Details

|